Are you facing challenges in managing and processing large volumes of waste 1 efficiently? Handling bulky materials can be time-consuming and costly, often leading to operational inefficiencies. However, understanding the fundamental aspects of horizontal hydraulic balers 2 can revolutionize your waste management process.

Horizontal hydraulic balers are sophisticated machines designed to compress and process waste materials into compact bales, enhancing storage and transportation efficiency while reducing operational costs.

Imagine transforming heaps of waste into neatly packed bales with ease, significantly improving your recycling efforts and overall operational productivity.

How does a baler machine work step by step?

Operating a baler machine involves a series of systematic steps that ensure waste is efficiently compressed into manageable bales. Understanding each step is crucial for maximizing the machine’s effectiveness and longevity.

A baler machine works by loading waste materials, compressing them using hydraulic or mechanical force, securing the bale, and then ejecting it for storage or transportation.

When we first implemented a baler machine in our facility, following a structured process helped us achieve consistent bale quality and maintain smooth operations.

Step-by-Step Operation

1. Preparation

Ensure the baler is properly installed and connected to a power source. Check that all safety features are in place and functioning correctly.

2. Loading the Waste

Feed the waste materials into the compression chamber. Depending on the baler type, this can be done manually or using an automated feeding system.

3. Compression

Activate the hydraulic or mechanical system to compress the waste. The pressure applied reduces the volume of the waste, forming a dense bale.

4. Securing the Bale

Once compressed, the bale is tied using wire, twine, or straps. This step secures the bale, making it easy to handle and transport.

5. Ejecting the Bale

The finished bale is ejected from the baler and can be moved to storage or transportation areas.

6. Resetting the Machine

Prepare the baler for the next cycle by ensuring it is clean and ready to receive more waste.

Maintenance Tips for Efficient Operation

- Consistent Loading: Maintain a steady flow of waste to prevent interruptions.

- Regular Maintenance: Keep the baler clean and perform routine checks to ensure optimal performance.

- Proper Tying: Use the appropriate tying materials to secure the bales effectively.

- Monitor Compression Levels: Adjust settings based on the type and volume of waste for best results.

How does a horizontal baler work?

A horizontal baler operates by compressing waste materials into dense bales through a combination of mechanical movements and hydraulic pressure. Unlike vertical balers, horizontal balers process materials on a horizontal plane, allowing for larger bale sizes and higher capacity.

Horizontal balers efficiently compress waste by utilizing a combination of mechanical movements and hydraulic pressure to form dense, manageable bales.

When we first integrated a horizontal baler into our facility, the increased capacity and efficiency transformed our waste management process, allowing us to handle larger volumes of waste with ease.

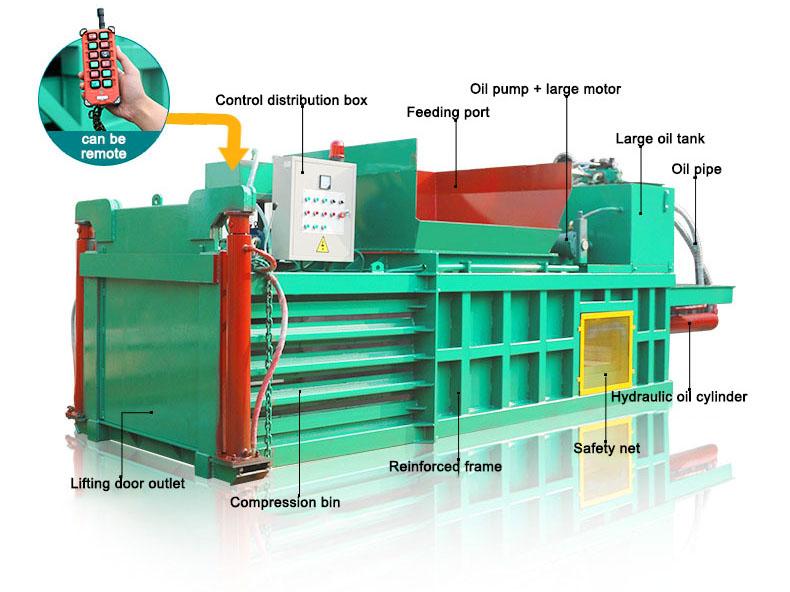

Components of a Horizontal Baler

Compression Chamber

The compression chamber is where waste materials are fed and compressed. It consists of steel plates that move horizontally to apply pressure to the waste.

Hydraulic System

The hydraulic system provides the necessary force to compress the waste. It includes hydraulic cylinders, pumps, and valves that control the movement and pressure during the baling process.

Tying Mechanism

Once the waste is compressed into a bale, the tying mechanism secures the bale with wire, twine, or straps to ensure it remains compact during handling and transportation.

Benefits of Horizontal Balers

| Feature | Benefit |

|---|---|

| Large Compression Chamber | Handles high volumes of waste efficiently |

| Hydraulic System | Provides consistent and powerful compression |

| Automated Tying | Saves time and reduces manual labor |

| Durable Construction | Built to withstand heavy-duty operations |

What is the process of baling?

Understanding the baling process is essential for optimizing efficiency and ensuring high-quality bales. A systematic approach can help achieve consistent and effective baling operations.

The baling process involves loading materials, compressing them into a dense form, securing the bale, and then ejecting it for storage or transportation.

When we refined our baling process, each step became more streamlined, resulting in higher efficiency and better-quality bales that consistently met our operational needs.

Step-by-Step Baling Process

1. Loading the Materials

Begin by feeding the waste materials into the baler’s hopper. Ensure that the materials are evenly distributed to promote uniform compression and prevent jams.

2. Compression

Activate the baler’s compression mechanism, which uses hydraulic or mechanical force to press the materials into a dense bale. The level of compression can be adjusted based on the type of material being baled.

3. Securing the Bale

Once compressed, the baler secures the bale using wires, twine, or straps. This step ensures that the bale remains compact and stable during handling and transportation.

4. Ejecting the Bale

After securing, the bale is ejected from the baler. It can then be moved to a storage area or loaded onto transportation vehicles for disposal or recycling.

5. Resetting the Machine

Prepare the baler for the next cycle by ensuring it is clean and ready to receive more waste.

Enhancing the Baling Process

| Step | Enhancement Tip |

|---|---|

| Loading | Use conveyors or automated feeding systems to increase speed and reduce manual labor |

| Compression | Adjust hydraulic settings to match material density for optimal compression |

| Securing | Choose the appropriate tying material based on bale size and weight |

| Ejecting | Implement smooth ejection mechanisms to prevent bale deformation |

| Maintenance | Perform regular checks and servicing to keep the baler in good working condition |

What is the working principle of baler?

The working principle of a baler revolves around the compression of waste materials into compact bales using mechanical and hydraulic force. This principle ensures that waste is efficiently managed, reducing both its volume and the associated costs of storage and transportation.

A baler’s working principle involves feeding waste into a compression chamber, applying pressure to form a bale, and then securing the bale for easy handling and disposal.

Implementing a baler in our operations transformed our waste management approach. The systematic compression process not only saved space but also enhanced our recycling capabilities.

Key Steps in the Baling Process

Feeding

Waste materials are fed into the baler either manually or automatically. Consistent feeding is crucial for maintaining the efficiency of the baling process.

Compression

The baler applies significant pressure to the waste, compressing it into a dense form. This step is essential for reducing the overall volume of the waste.

Tying

After compression, the bale is tied securely to maintain its shape and integrity during handling and transportation.

Types of Materials Suitable for Balers

- Cardboard and Paper: Easily compressed into bales for recycling.

- Plastics: Can be baled for efficient recycling and disposal.

- Metal Scrap: Compressed into dense bales for transportation.

- Textiles: Baled for recycling or disposal.

Benefits of the Working Principle

| Aspect | Benefit |

|---|---|

| Volume Reduction | Decreases storage space needed for waste |

| Cost Efficiency | Lowers transportation and disposal expenses |

| Recycling Enhancement | Facilitates easier sorting and processing of recyclables |

| Operational Safety | Minimizes clutter and reduces workplace hazards |

Conclusion

Understanding the basic structure, workflow, and core technology of horizontal hydraulic balers is essential for optimizing your waste compression and processing operations. By comprehensively grasping how these balers work, the step-by-step baling process, and the underlying working principles, you can enhance efficiency, reduce costs, and promote sustainable recycling practices.

Implementing a horizontal hydraulic baler in your facility can transform your waste management system, making it more organized, efficient, and cost-effective. Whether you’re managing a manufacturing plant, a recycling center, or a large retail store, a horizontal hydraulic baler can meet your waste compression and processing needs effectively.

For more information on our range of high-quality, customizable horizontal hydraulic balers, feel free to reach out to me at [email protected] or visit our website Sybaling Machine.

-

Efficient waste management is crucial for businesses that handle significant amounts of waste, such as manufacturing or distribution companies. This resource will explain the most effective strategies to manage large waste volumes and the tools that can help streamline the process. ↩

-

A horizontal hydraulic baler is a type of baler used to compact and bind waste materials such as cardboard and plastics into dense, manageable bales. This link will give you a detailed overview of how horizontal hydraulic balers work and why they are an excellent choice for managing large volumes of waste efficiently. ↩