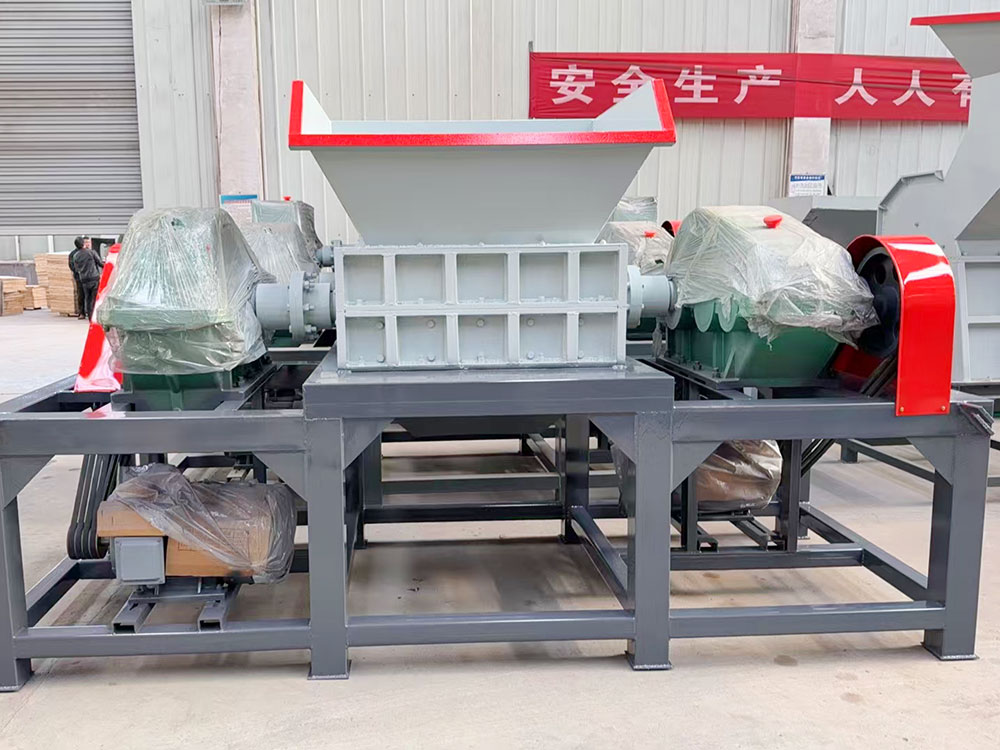

Our industrial shredder machine efficiently processes waste materials like plastics, paper, wood, and light metals. Built for durability and performance, it features hardened steel blades, powerful motor options, and customizable configurations to meet specific recycling needs. The machine reduces waste volume by up to 80%, significantly cutting disposal costs while improving recycling efficiency. Ideal for recycling plants, manufacturing facilities, and waste management operations.

Stop wasting money on inefficient waste disposal. Our industrial shredder machine cuts your waste volume dramatically – saving storage space and transportation costs while creating new revenue from recycling.

Example Parameters:

| Model | SY-300 |

| Use | Paper Shredder Machine |

| Power | 3KW |

| Voltage | 380V 50HZ 3Phase |

| Rotating speed | 16/min |

| Torque | 1628Nm |

| Input shaft diameter | Φ50 |

| Blade size and material | Φ180*12,9CrSi |

| Number of blades | 24 |

| Size of feeding port | 500*500*300mm |

| Width of outlet | 450mm |

| Height of the feeding port above the ground | 200mm |

| Dimension(L*W*H) | 1040*570*1380mm |

| Machine Weigh | 400 kg |

Key Features:

- Powerful Cutting Performance: High-torque motors and toughened steel blades handle demanding materials without jamming

- Customizable Designs: Choose from single/double shaft configurations with various feeding systems

- Cost Efficient: Reduces waste volume by 80%, lowering disposal expenses

- Safe Operation: Integrated safety features including emergency stop and overload protection

- Low Maintenance: Easy access for cleaning and blade replacement

- Energy Smart: Optimized power consumption for economical operation

Available Models:

- Small Capacity (15-30HP) for light industrial use

- Medium Capacity (30-60HP) for factories and recycling centers

- Heavy Duty (60-100HP) for large-scale waste processing

Why Buy From Our Factory?

Manufacturer Direct Pricing

- No middlemen means 25-40% cost savings compared to dealers

- Bulk order discounts available

Certified Quality Assurance

- ISO 9001 & CE certified production facility

- Each machine undergoes strict quality testing

Fast Turnaround

- Standard models ship in 7-14 days

- Custom orders delivered in 15-30 days

Global Export Experience

- Established shipping networks to North America, Japan, and Singapore

- Handle all export logistics and documentation

Complete After-Sales Support

- 12-month warranty with lifetime technical support

- Remote troubleshooting available

- Global spare parts supply network

Frequently Asked Questions

What maintenance does the shredder require?

Basic maintenance includes blade sharpening every 3-6 months (depending on use), regular lubrication of moving parts, and periodic motor inspection. We provide detailed maintenance manuals with each machine.

Can the machine be customized for specific materials?

Yes, we offer custom blade configurations, feeding systems, and processing chambers optimized for different materials like e-waste, plastic film, or wood waste.

What specifications should I consider when choosing a model?

Key factors include: material type/hardness, desired output size, hourly processing capacity, and available power supply. Our engineers can help select the perfect model for your needs.

How noisy is the machine during operation?

Our sound-insulated models operate at 70-75dB (similar to a vacuum cleaner). Special low-noise versions (under 65dB) are available for urban locations.

What payment methods do you accept?

We accept T/T, L/C, and Western Union. For first-time buyers, we can discuss payment terms to build trust.

Do you offer commissioning and training?

Yes, we provide installation manuals, video guides, and can arrange engineers for on-site commissioning (travel costs apply). Basic operator training is always included.

How do I order spare parts?

Simply email us your machine model and required parts. We maintain a global parts inventory for fast shipping anywhere.