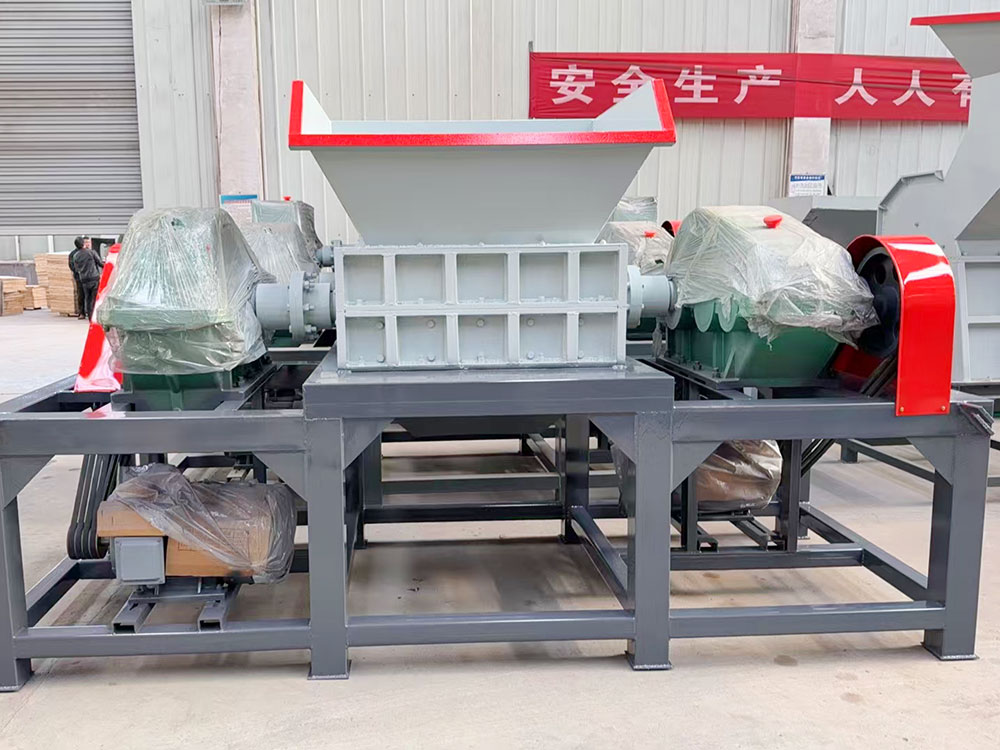

Our industrial shredder machine cuts and processes various waste materials into smaller pieces. It helps recycling plants and factories handle paper, plastic, wood, and metal scraps efficiently. The tough blades can shred tough items without jamming. The machine runs quietly while staying powerful. Many waste management companies use our shredders to reduce transport costs and prepare materials for recycling. You can choose different sizes and power levels to match your needs.

Do you need to handle large volumes of waste materials? Our shredder machine solves space and cost problems for factories. It helps you dispose of scraps safely and profitably.

Example Parameters:

| Model | SY-300 |

| Use | Paper Shredder Machine |

| Power | 3KW |

| Voltage | 380V 50HZ 3Phase |

| Rotating speed | 16/min |

| Torque | 1628Nm |

| Input shaft diameter | Φ50 |

| Blade size and material | Φ180*12,9CrSi |

| Number of blades | 24 |

| Size of feeding port | 500*500*300mm |

| Width of outlet | 450mm |

| Height of the feeding port above the ground | 200mm |

| Dimension(L*W*H) | 1040*570*1380mm |

| Machine Weigh | 400 kg |

Our shredder machine offers three key benefits. First, the sharp blades stay sharp for a long time. We use special steel that resists wear. Second, the machine works fast without making much noise. Workers can operate it comfortably. Third, the design is simple but very strong. It rarely breaks down even with tough materials.

The shredder helps companies save money in many ways. It reduces waste volume by up to 80%. This means fewer truck trips to landfills. The processed materials also fetch better prices from recyclers. Many customers recover their investment within one year.

We make shredders for all common materials. They work well with plastic bottles, paper rolls, wood pallets, and thin metal sheets. The machines can run for hours without overheating. Our engineers test each machine thoroughly before shipment.

As a factory with five production lines, we offer special advantages. We control quality at every step from raw materials to finished machines. Our workers have over ten years of experience making shredders. The factory has modern equipment to ensure precision.

We customize shredders for specific needs. Customers can choose blade types, power levels, and feeding systems. Our prices stay low because we make the machines ourselves. There are no middlemen adding extra costs.

Our machines meet international safety standards. We hold several certifications that buyers require. Many customers from North America and Japan trust our products. We help with paperwork for customs clearance too.

The factory ships machines quickly. We keep common models in stock. For special orders, we give accurate delivery dates and keep customers updated. Our technicians can install the machines worldwide.

FAQ:

Q1: Where can I find reliable shredder machine suppliers in China? A: Search for factories with ISO certification and years of experience. Check if they export to developed countries. Visit their facilities if possible before ordering.

Q2: What power capacity do I need for a small recycling plant? A: For small plants handling 1-2 tons daily, start with a 15-25HP motor. Measure your typical material volume first to choose correctly.

Q3: How do Chinese shredder machine prices compare to European brands? A: Chinese machines often cost 30-50% less with similar quality. Savings come from lower labor costs and local material supplies.

Q4: Can I get a test machine before bulk ordering? A: Many Chinese factories offer sample machines for testing. Pay just for shipping to check performance first.

Q5: What maintenance does a shredder require? A: Basic care includes blade sharpening every 3-6 months and regular grease application. Replace worn parts promptly to avoid damage.