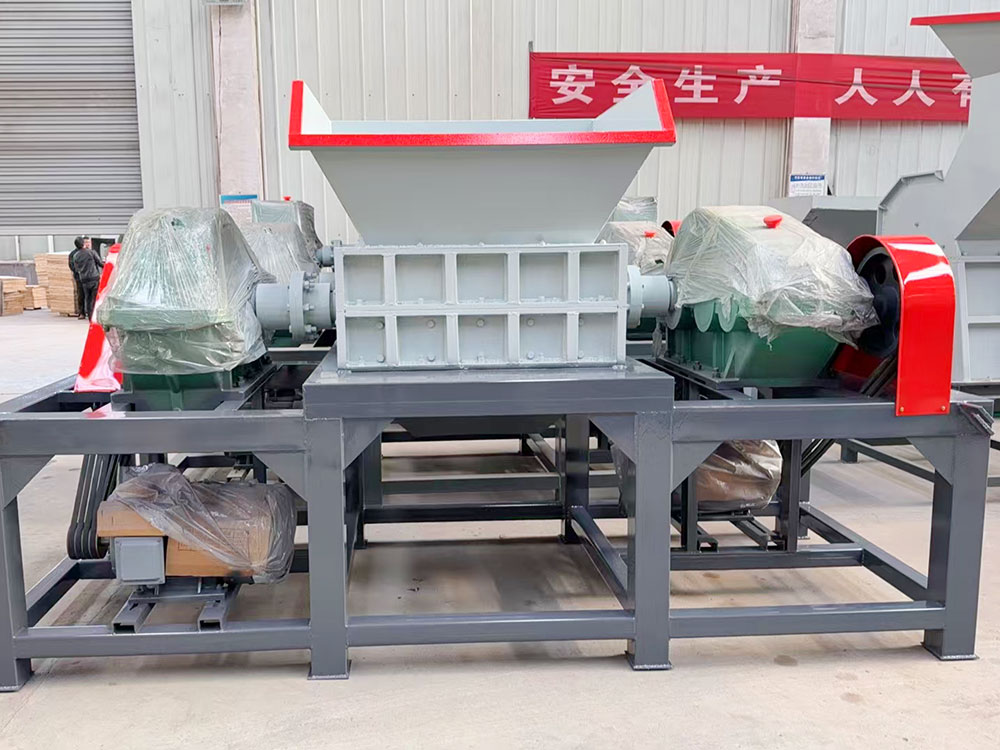

Our heavy-duty industrial shredder machine efficiently shreds plastic, paper, wood and light metal waste for recycling. Built for continuous operation in demanding environments, it features durable construction, powerful motors, and customizable options. Reduce your waste volume up to 85% while lowering disposal costs and improving recycling efficiency.

Struggling with overflowing waste bins and high disposal costs? Our industrial shredder cuts waste volume immediately – saving space, transportation fees and creating new recycling revenue streams.

Example Parameters:

| Model | SY-300 |

| Use | Paper Shredder Machine |

| Power | 3KW |

| Voltage | 380V 50HZ 3Phase |

| Rotating speed | 16/min |

| Torque | 1628Nm |

| Input shaft diameter | Φ50 |

| Blade size and material | Φ180*12,9CrSi |

| Number of blades | 24 |

| Size of feeding port | 500*500*300mm |

| Width of outlet | 450mm |

| Height of the feeding port above the ground | 200mm |

| Dimension(L*W*H) | 1040*570*1380mm |

| Machine Weigh | 400 kg |

Why Our Shredder Stands Out

Powerful Performance

- High-torque motors maintain speed under load

- Multi-stage cutting system handles tough materials

- Automatic reverse function prevents jams

Built to Last

- 20mm thick steel frame resists vibration

- Hardened blades last 3-5x longer than standard

- Reinforced bearings for heavy loads

Smart Operation

- Easy-access control panel with auto-stop

- Low noise (<75dB) with sound insulation

- Quick-change blades reduce downtime

Cost Savings

- Reduces waste handling costs by 40-60%

- Energy efficient motors cut power bills

- Low maintenance design

Factory Advantages

Direct Manufacturer Pricing – No middlemen means you save 30% compared to dealers

Custom Solutions Available

- Special configurations for specific materials

- Branding and color options

- Different voltage/frequency models

Fast Production & Delivery

- Standard models ready in 7 days

- Worldwide shipping experience

- Help with customs clearance

Quality Guaranteed

- ISO 9001 & CE certification

- Each machine tested before shipment

- 12-month warranty

After-Sales Support

- English-speaking technicians

- Online troubleshooting

- Global spare parts network

Common Questions

What typical materials can be shredded?

Our machines handle plastic (bottles, film, pipes), paper/cardboard, wood (pallets, furniture), rubber, and light metals (aluminum cans, wire).

How often do blades need replacement?

With normal use, blades last 6-12 months before sharpening and 2-3 years before replacement. We provide blade replacement instructions.

Is installation complicated?

Standard models require basic mechanical skills and electrical connection. We provide:

- Detailed installation manual

- Video guides

- Phone/email support

What about safety features?

Includes emergency stop button, overload protection, and safety lock system. Optional safety light curtains available.

Minimum order quantity?

We accept single unit orders. Larger orders get better pricing discounts.

Payment terms?

30% deposit, 70% before shipment for new customers. Established buyers can discuss better terms.

Shipping time to North America?

Approximately 25-35 days door-to-door including customs clearance.