Maximize Density, Minimize Costs – The Intelligent Waste Compaction Solution

Why choose a fully automatic horizontal hydraulic baler?

Experience seamless, hands-free baling with our fully automatic horizontal baler. Perfect for high-volume operations.

How about a traditional manual baler?

Requires a lot of labor

Uneven packing density

Low production efficiency

What can the fully automatic baling machine solve?

PLC fully automatic operation, reducing labor

High pressure compression, uniform density

Continuous feeding, uninterrupted packaging

How to choose the right horizontal baler for you?

“Safe design | Suitable for cartons, plastics, | Easy to operate”

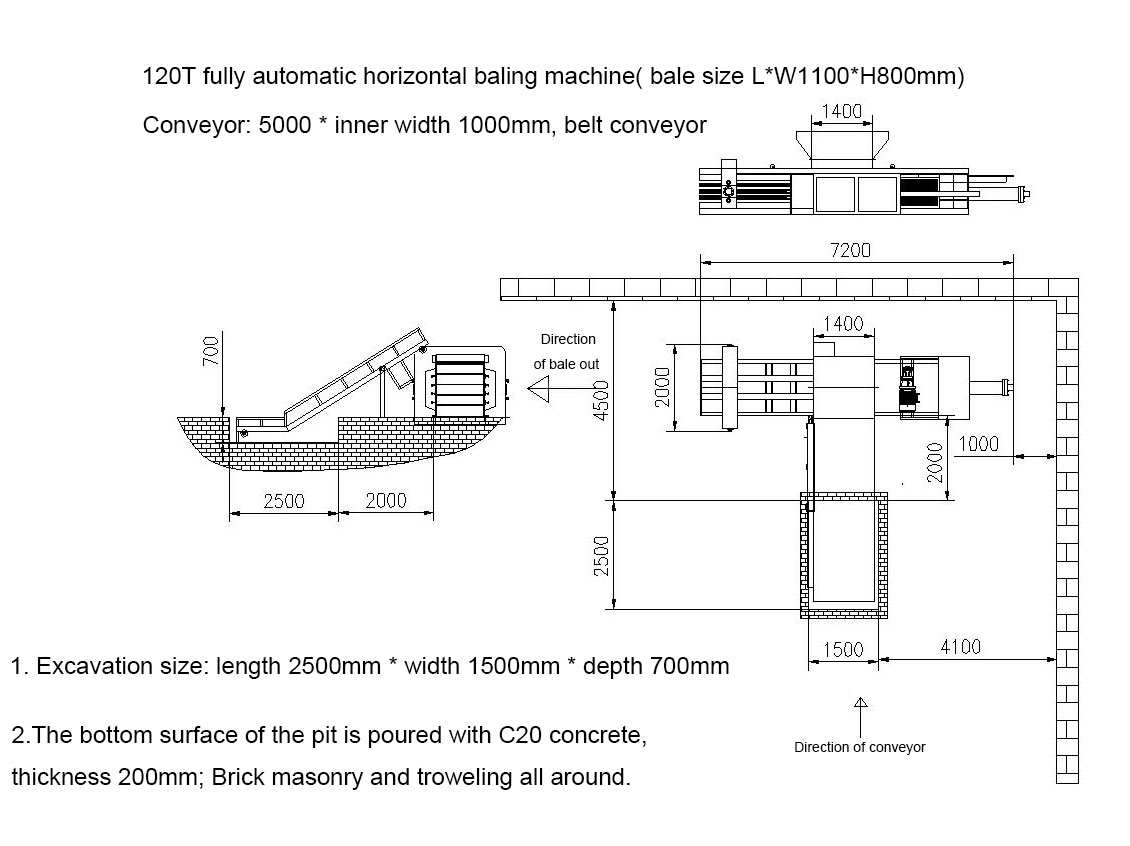

Pressure: Customer Cases 120T (Customization available, up to 300T+)

Degree of automation: Automatic packing , Manual rope threading , Manual rope binding

Baler size: L1700*W1100*H850 mm

Bale weight: 300-400 kg for PET bottles , 500-600kg for cardboard

Inlet: 1400*1100 mm

Main cylinder: 230 mm*2800 mm

Outlet method: Cylinder push bag

Working efficiency: 4-6 pieces/h

Operating system (Mitsubishi/Xinjie): Control box

Motor: 22 KW

Voltage: 380V/50 HZ/ 3phase/ 900 RPM

Install a lift door baler, increasing efficiency by 30% !

Saves 50% labor cost than traditional baler !

Q1: How does your baler solve the problem of large waste area?

A: EcoPress HD series uses an ultra-high compression ratio of 15:1 (industry average 8:1) to turn loose waste into standard cubes with a density of 800-1200kg/m³:

✓ Metal chips volume reduced by 87%

✓ Waste textile stacking height reduced by 64%

✓ No need to rent additional stacking space | Save ¥50,000+ warehouse rent per month

Q2: Can the processing efficiency keep up with the pace of continuous production?

A: Patented 5-second ultra-fast compression cycle system (including automatic wire feeding/bundling):

→ Daily processing capacity of 75 tons of metal chips (based on HD-300 model)

→ Intelligent early warning system to prevent material jamming and interruption, failure rate <0.5%

→ Case verification: A certain auto parts factory increased its production capacity by 230% after replacing old equipment

Q3: How to ensure the safety of 220-ton pressure equipment?

A: Triple protection to protect the operator:

① Two-hand button start + infrared light curtain real-time monitoring

② German Bosch hydraulic lock (0.1 second self-locking when pressure is abnormal)

③ CE/PED certification for the whole machine + ISO 12100 PLd safety level

▶️ 7 consecutive years of zero work-related injuries

Q4: Do different types of waste (metal/plastic/textile) need to replace equipment?

A: No need to replace! Baleflex adaptive compression bin original solution:

Hydraulic system automatically matches pressure: metal chips (220 tons) → plastic bottles (80 tons)

3-hour quick change mode: free switching between wire bundles/belt bundles

Hopper anti-hanging coating treatment to eliminate fiber residues

Q5: Is the maintenance cost high? Is there any local technical support?

A: We promise that lifetime costs are controllable:

◆ 10-year main steel structure warranty (Hardox 450 wear-resistant steel plate)

◆ 72-hour global emergency response: 16 spare parts centers in Asia/Europe/America

◆ Profit Booster™ system warns of replacement of consumable parts 90 days in advance

◆ 24h remote AR maintenance guidance in Chinese/English/Spanish