Unlocking Next-Level Waste Processing Efficiency for Industrial Buyers

Why choose a fully automatic horizontal hydraulic baler?

Experience seamless, hands-free baling with our fully automatic horizontal baler. Perfect for high-volume operations.

How about a traditional manual baler?

Requires a lot of labor

Uneven packing density

Low production efficiency

What can the fully automatic baling machine solve?

PLC fully automatic operation, reducing labor

High pressure compression, uniform density

Continuous feeding, uninterrupted packaging

How to choose the right horizontal baler for you?

“Safe design | Suitable for cartons, plastics, | Easy to operate”

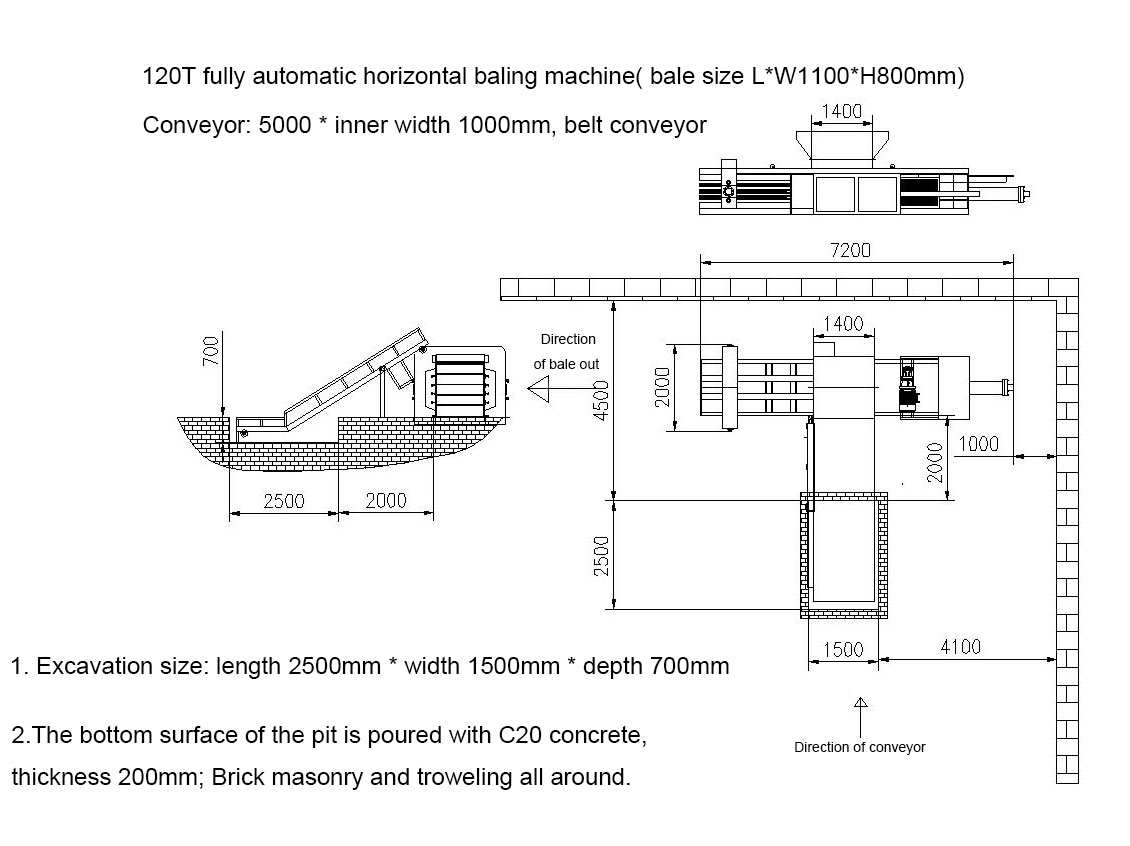

Pressure: Customer Cases 120T (Customization available, up to 300T+)

Degree of automation: Automatic packing , Manual rope threading , Manual rope binding

Baler size: L1700*W1100*H850 mm

Bale weight: 300-400 kg for PET bottles , 500-600kg for cardboard

Inlet: 1400*1100 mm

Main cylinder: 230 mm*2800 mm

Outlet method: Cylinder push bag

Working efficiency: 4-6 pieces/h

Operating system (Mitsubishi/Xinjie): Control box

Motor: 22 KW

Voltage: 380V/50 HZ/ 3phase/ 900 RPM

Install a lift door baler, increasing efficiency by 30% !

Saves 50% labor cost than traditional baler !

How Automation Revolutionizes Baling Operations

Witness productivity surge as our horizontal balers automate the entire workflow – from feeding to strapping. Intelligent PLC systems monitor material density for consistent 400-1200kg bales at 20+ cycles/hour. Operators simply load waste while sensors control compression timing, eliminating jams in textile recycling plants and distribution centers.

Military-Grade Construction Endures Industrial Abuse

Heavy-duty frames forged from S355JR structural steel undergo sandblasting before triple-layer painting. 56mm thick compression plates withstand daily 350-ton forces without deformation. Hydraulic systems feature Parker Hannifin pumps with built-in overheating protection – proven in 24/7 PET recycling facilities.

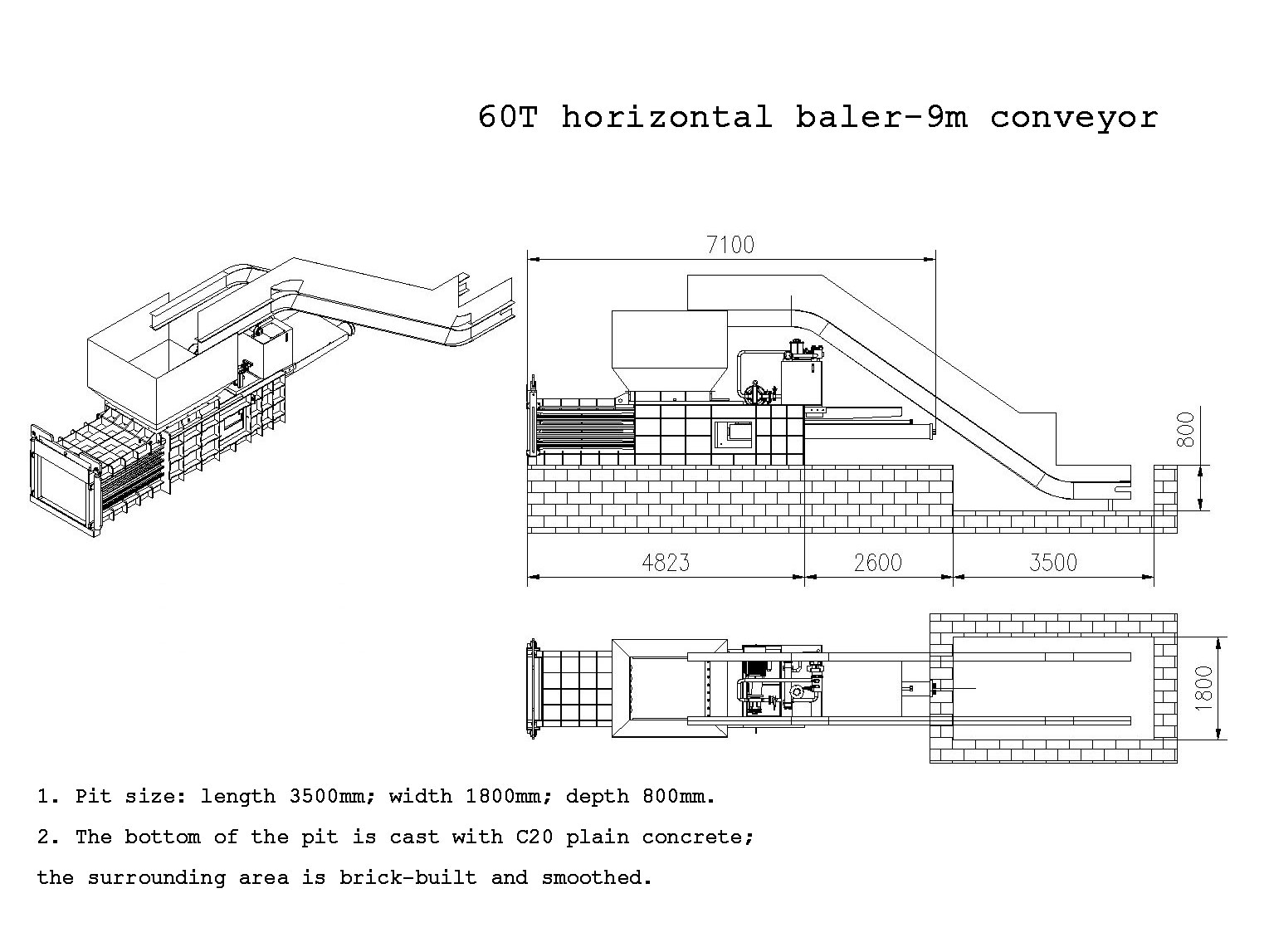

Complete Configuration Flexibility

Select optional integrated conveyor systems, add duplex paper feeding, or request emergency stop systems. Choose bale sizes between 110x90cm and 130x110cm. Control cabinets pre-configured for Canadian CSA standards with French/English interfaces. Custom color schemes available for corporate rebranding.

Anti-Fraud Documentation Protocol

Demand authenticity: All CE/PED/ASME certificates feature QR codes linking to real-time verification portals. View your machine’s construction process through factory live cams. Receive signed material test reports from certified third-party labs. 100% performance validation with your materials before shipment.

Hassle-Free Import to Canadian Facilities*Streamlined door-to-door delivery to Toronto/Montreal/Vancouver:

Prepaid customs clearance (HS Code 846239)

ISPM 15-compliant wood crating

Temperature-controlled container shipping

Payment security: L/C or 30% deposit with 70% balance against B/L copies