Precision Compression for Maximum Material Recovery

Why choose a fully automatic horizontal hydraulic baler?

Experience seamless, hands-free baling with our fully automatic horizontal baler. Perfect for high-volume operations.

How about a traditional manual baler?

Requires a lot of labor

Uneven packing density

Low production efficiency

What can the fully automatic baling machine solve?

PLC fully automatic operation, reducing labor

High pressure compression, uniform density

Continuous feeding, uninterrupted packaging

How to choose the right horizontal baler for you?

“Safe design | Suitable for cartons, plastics, | Easy to operate”

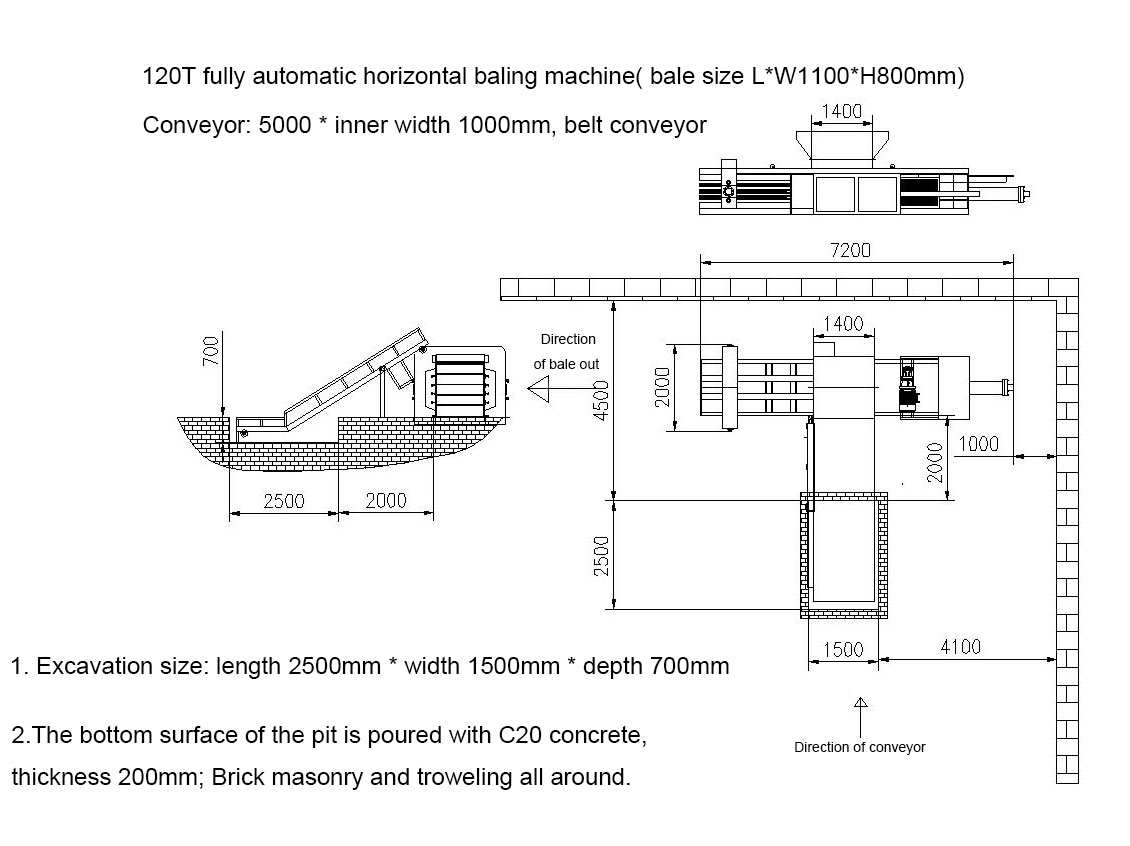

Pressure: Customer Cases 120T (Customization available, up to 300T+)

Degree of automation: Automatic packing , Manual rope threading , Manual rope binding

Baler size: L1700*W1100*H850 mm

Bale weight: 300-400 kg for PET bottles , 500-600kg for cardboard

Inlet: 1400*1100 mm

Main cylinder: 230 mm*2800 mm

Outlet method: Cylinder push bag

Working efficiency: 4-6 pieces/h

Operating system (Mitsubishi/Xinjie): Control box

Motor: 22 KW

Voltage: 380V/50 HZ/ 3phase/ 900 RPM

Install a lift door baler, increasing efficiency by 30% !

Saves 50% labor cost than traditional baler !

High-Speed Bale Production Simplified

Our automatic press machines compress waste into uniform bales effortlessly. Twin hydraulic cylinders generate over 280 tons of force – processing cardboard, plastics, or textiles at 15+ cycles/hour. Auto-tie systems secure bales without operator intervention, cutting labor costs while maintaining consistent 500kg density outputs.

Industrial Hydraulic Power for Continuous Operation

Built with Hardox 450 steel frames tested under ISO 6508 standards. Integrated cooling systems prevent overheating during sustained operation. Japanese Yuken valves synchronize press movements within ±0.5mm precision. Every pump undergoes 48-hour dry-run testing before shipping.

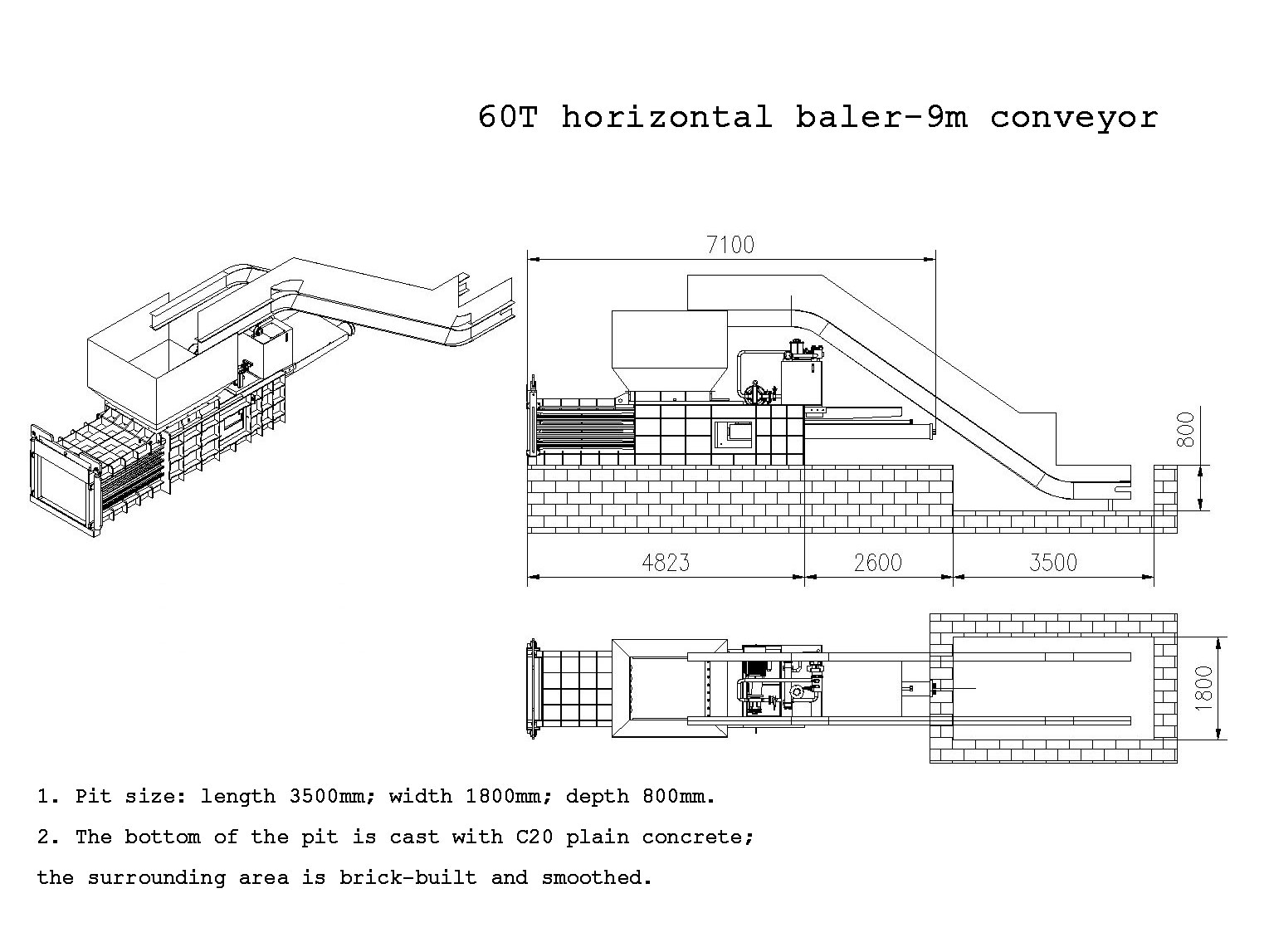

Adaptable Press Configurations for Any Space

Choose single or dual ram systems with 1.3-2.1m bale chambers. Customize discharge heights (0.8-1.4m) to match conveyor systems. Add explosion-proof motors or hydraulic scrap feeders. Control panels support multilingual interfaces including French/English for Canadian operations.

Verifiable Quality Documentation Guarantees Value

Demand genuine CRN, ASME, and CSA certifications – we provide original papers with QR traceability codes. Optional video factory audits during production. Performance tests conducted using your material samples before shipping. All electrical components carry UL listings.

Canada-Bound Machinery Shipments Simplified

Door-to-door shipping to Toronto/Montreal in 20 days with duties prepaid. Fumigation according to CFIA standards. Flexible payment structure: 30% deposit, 40% pre-shipment, 30% post-acceptance. Receive real-time container loading photos and GPS-tracked shipments.