Maximize Waste Recycling Efficiency with Hydraulic Automation

Why choose a fully automatic horizontal hydraulic baler?

Experience seamless, hands-free baling with our fully automatic horizontal baler. Perfect for high-volume operations.

How about a traditional manual baler?

Requires a lot of labor

Uneven packing density

Low production efficiency

What can the fully automatic baling machine solve?

PLC fully automatic operation, reducing labor

High pressure compression, uniform density

Continuous feeding, uninterrupted packaging

How to choose the right horizontal baler for you?

“Safe design | Suitable for cartons, plastics, | Easy to operate”

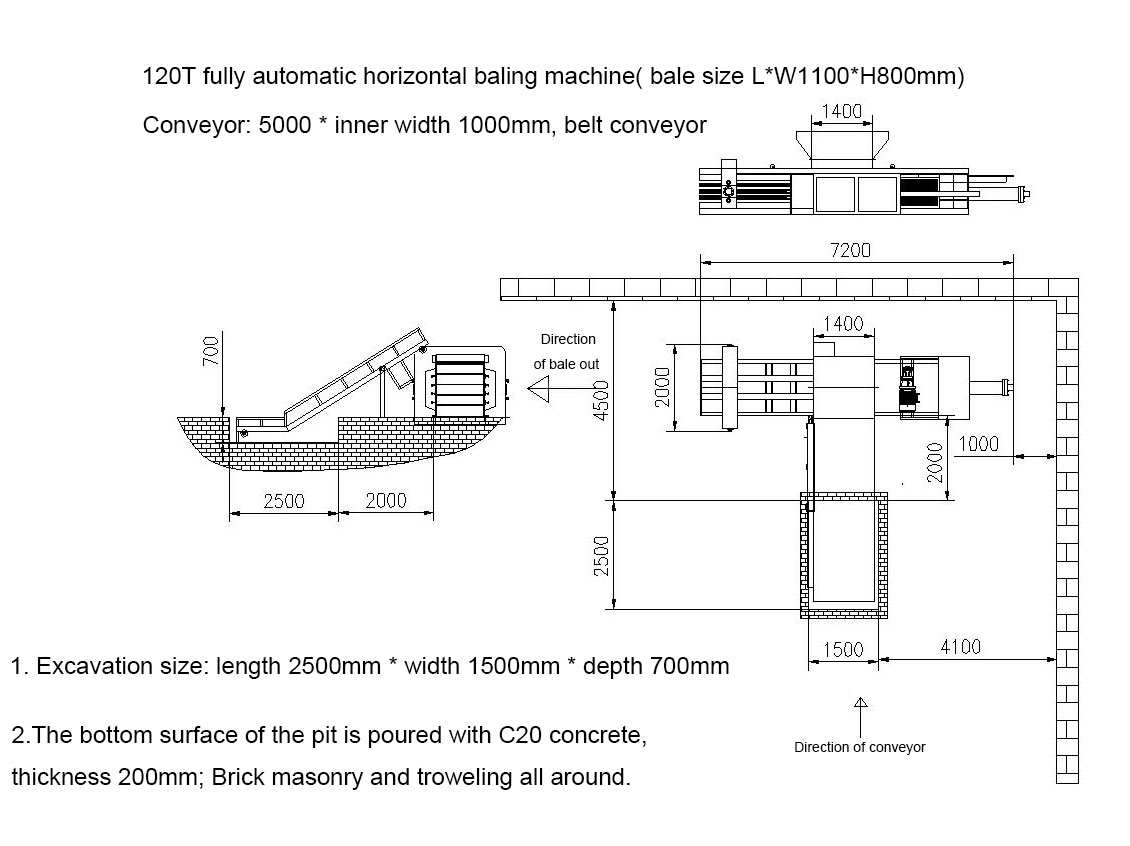

Pressure: Customer Cases 120T (Customization available, up to 300T+)

Degree of automation: Automatic packing , Manual rope threading , Manual rope binding

Baler size: L1700*W1100*H850 mm

Bale weight: 300-400 kg for PET bottles , 500-600kg for cardboard

Inlet: 1400*1100 mm

Main cylinder: 230 mm*2800 mm

Outlet method: Cylinder push bag

Working efficiency: 4-6 pieces/h

Operating system (Mitsubishi/Xinjie): Control box

Motor: 22 KW

Voltage: 380V/50 HZ/ 3phase/ 900 RPM

Install a lift door baler, increasing efficiency by 30% !

Saves 50% labor cost than traditional baler !

How Automatic Horizontal Balers Transform Operations

These machines rapidly compress recyclables into dense blocks using PLC-controlled hydraulic systems. No manual tying required – automated strapping secures each bale for consistent 150-1500kg outputs. Operators simply load materials; sensors trigger compression cycles when chambers fill, preventing jams during cardboard, textile, or PET bottle processing.

Engineering Excellence Behind Our Hydraulic Press Technology

We build 42CrMo steel frames with triple-welded seams, sustaining 500-ton compression forces. German Rexroth hydraulic pumps deliver >50 cycles/hour without overheating, while Japanese NAKADE seals eliminate oil leaks for 24/7 operation. Each cylinder undergoes MPI testing before assembly.

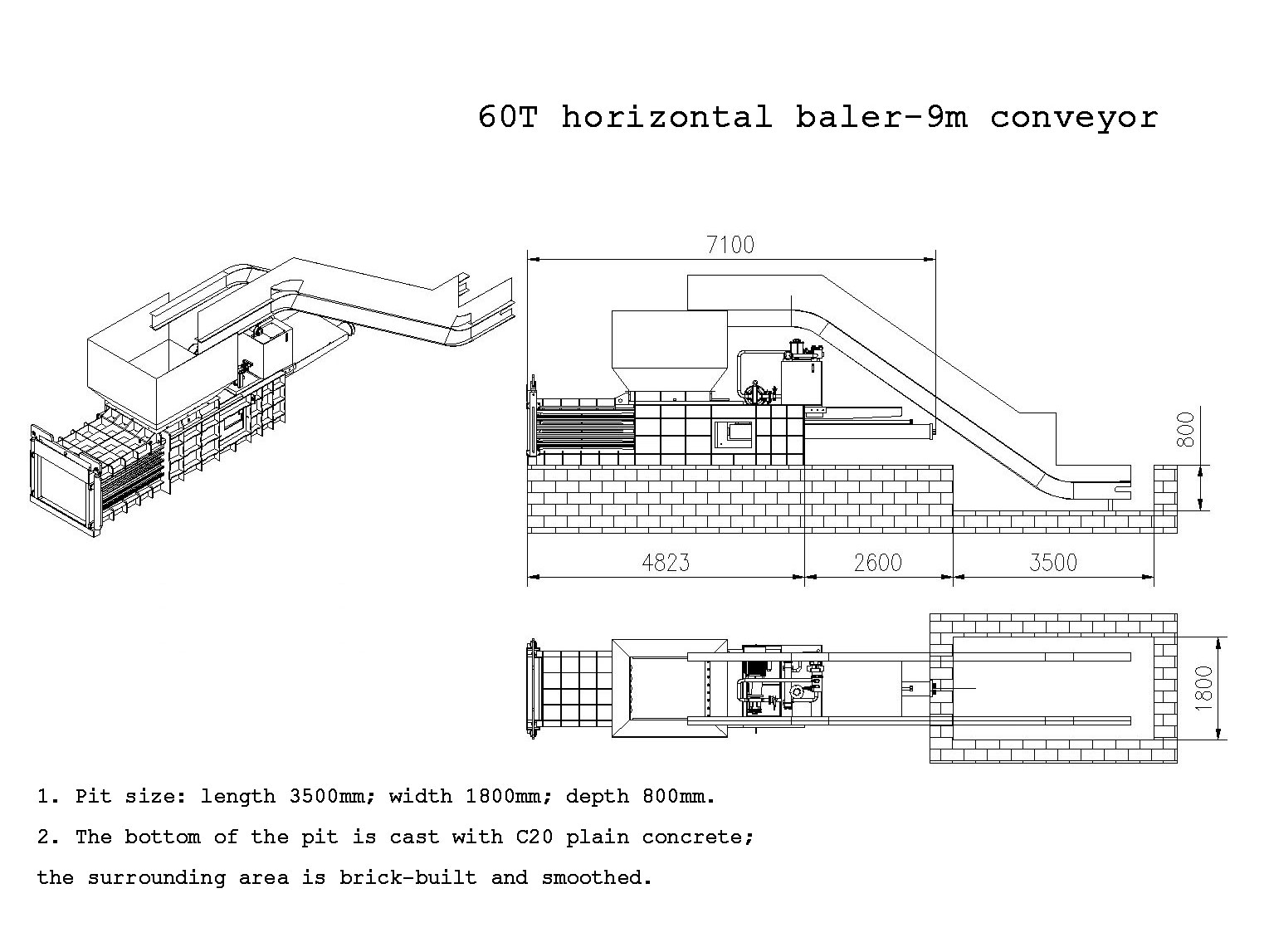

Customizable Designs for Your Business Needs

Request modular configurations: Add conveyors, explosion-proof motors, or dual-chamber options. Adjust bale dimensions from 1200x900mm to 1500x1100mm. We’ll pre-wire control panels to your factory voltage. All balers ship with CE/PED/FDA compliance documentation (certificates viewable pre-shipment).

Quality Assurance That Protects Your Investment

Watch real-time production via our factory livestream during manufacturing. We provide video proof of performance tests using scrap materials you specify – run trials with metal scraps, e-waste, or agricultural film. Three-year warranty covers structural defects with lifetime technical support.

Streamlined Global Logistics for Canadian Importers

Your baler arrives DDP Toronto/Vancouver in 18 days. We handle customs, ISPM-15 fumigation, and loading. Payment options: 30% TT deposit, 70% against BL copies. Request C$ pricing to avoid USD fluctuations. Container loading videos provided pre-shipment.