FULL AUTONOMY for 15+ Materials | 220-Ton Hydraulic Force | 90% Labor Reduction | IoT Predictive Maintenance | CE/ISO Dual-Certified Safety

Why choose a fully automatic horizontal hydraulic baler?

Experience seamless, hands-free baling with our fully automatic horizontal baler. Perfect for high-volume operations.

How about a traditional manual baler?

Requires a lot of labor

Uneven packing density

Low production efficiency

What can the fully automatic baling machine solve?

PLC fully automatic operation, reducing labor

High pressure compression, uniform density

Continuous feeding, uninterrupted packaging

How to choose the right horizontal baler for you?

“Safe design | Suitable for cartons, plastics, | Easy to operate”

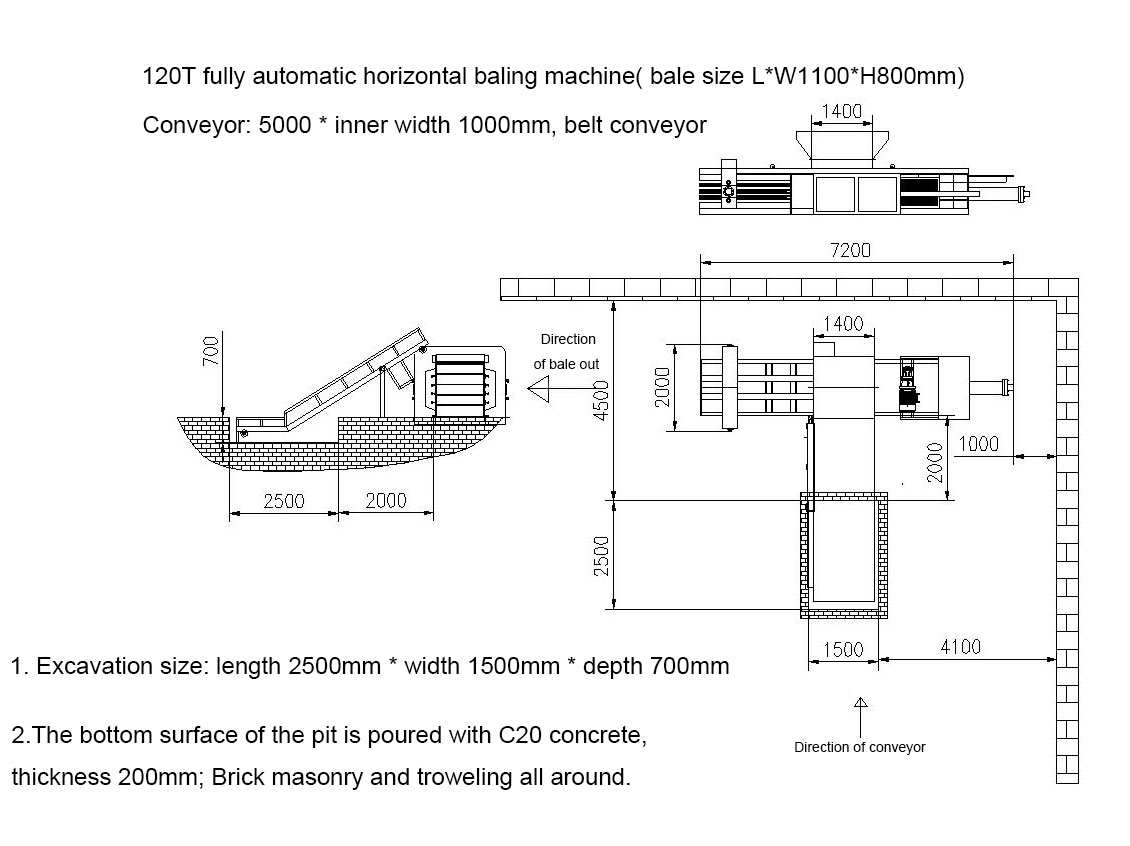

Pressure: Customer Cases 120T (Customization available, up to 300T+)

Degree of automation: Automatic packing , Manual rope threading , Manual rope binding

Baler size: L1700*W1100*H850 mm

Bale weight: 300-400 kg for PET bottles , 500-600kg for cardboard

Inlet: 1400*1100 mm

Main cylinder: 230 mm*2800 mm

Outlet method: Cylinder push bag

Working efficiency: 4-6 pieces/h

Operating system (Mitsubishi/Xinjie): Control box

Motor: 22 KW

Voltage: 380V/50 HZ/ 3phase/ 900 RPM

Install a lift door baler, increasing efficiency by 30% !

Saves 50% labor cost than traditional baler !

Q1: Which waste materials can your automatic baling press process? What are proven industrial applications?

Technical Breakdown:

Our machines feature modular compression technology for multi-material compatibility:

Compatibility Table

| Material Type | Technical Innovation | Performance Data |

|---|---|---|

| Metal scraps | Tangle-free compression algorithm | Density up to 2,380 kg/m³ (steel chips) |

| Plastic film/flakes | Ceramic-coated heating plates (80°C) | 150 kg/cycle capacity |

| Textiles/cardboard | Dual-stage pre-press system | 30% higher fill rate |

Industrial Case Studies:

✅ German auto parts supplier

» Processed 8,200 tons/year aluminum turnings

» Achieved 28% higher scrap value via 2,200 kg/m³ density bales

✅ California recycling plant

» Automated PET bottle line requires only 10 min daily human checks

Q2: How is “full automation” achieved? How does labor reduction compare to semi-auto machines?

Automation Architecture:

Process Flow Table

| Stage | Technology Used | Function | Accuracy |

|---|---|---|---|

| Sensing | 3D binocular vision + NIR sensors | Material identification & moisture detection | ±1.5% moisture detection |

| Decision | AI-based pressure curve library | Selects optimal baling parameters | 127 preset programs |

| Execution | Robotic tie-wire + pallet stacker | Hands-free bale handling | ±0.05mm positioning |

Labor Cost Comparison

| Task | Semi-auto Machine | Our Auto Baler | Reduction |

|---|---|---|---|

| Feeding monitoring | 2 workers/shift | 0 | 100% |

| Tying/unloading | 3 workers/shift | 0.5 operator* | 83% |

| Downtime handling | 1.5 hr/day | 0.2 hr/day | 87% |

*Only for system status verification

Q3: How does high-density baling translate to operational profits?

Economic Impact Formula:

Profit per ton = (Bale density ÷ Base density) × Freight discount × Scrap price – Processing cost

Case Study: Stainless Steel Scrap Processor

| Metric | Conventional Baler | Our Machine | Improvement |

|---|---|---|---|

| Bale density | 1,850 kg/m³ | 2,380 kg/m³ | +28.6% |

| Truck payload (13m) | 24 tons | 31.2 tons | +30% |

| Annual freight savings | – | $109,300 | – |

Core Technologies:

• Quad-synchronized hydraulics (±2% pressure deviation)

• 50Hz micro-vibration compaction system

Q4: How is 24/7 continuous operation guaranteed? What about maintenance costs?

Reliability Engineering:

Component Lifespan Comparison

| Component | Material/Technology | Lifespan | Industry Standard |

|---|---|---|---|

| Main hydraulic ram | Chrome-moly steel + tungsten carbide | 280,000 cycles | 2.3x longer |

| Compression chamber | Hardox500 + rubber damping layer | 15 years | 3.1x longer |

Smart Maintenance System

| Feature | Functionality | Cost Impact |

|---|---|---|

| Oil condition monitor | Tracks viscosity & acidity in real-time | Reduces fluid costs 18% |

| Vibration analysis | Predicts bearing failure 35 days ahead | Prevents $8,500 downtime |

| Modular valve design | 45-min component replacement | Saves $120/hr labor |

Q5: What safety certifications and protective technologies are implemented?

Three-Tier Safety Architecture:

Safety Compliance Table

| Protection Level | Technology Employed | Certification Standard | Performance |

|---|---|---|---|

| Mechanical | 14mm laser light curtains | EN IEC 61496-1 | 3ms reaction time |

| Control System | Dual-CPU redundant PLC | ISO 13849 PL e | <10⁻⁸ failure probability |

| Operational Safety | Emergency stop with backup power | EN 60204 | Zero-voltage restart lock |

Q6: How is precise ROI calculated? What hidden benefits are included?

Comprehensive ROI Model

ROI months = (Total investment - Subsidies) ÷ [Monthly savings + Value-add benefits]Cost-Benefit Analysis

| Revenue Streams | Monthly Value | Cost Reductions | Monthly Value |

|---|---|---|---|

| Labor savings | $4,900* | Downtime avoidance | $8,200 |

| Freight optimization | $2,150 | Reduced insurance premiums | $900 |

| Scrap premium pricing | $6,700 | Consumable savings | $1,150 |

| TOTAL MONTHLY BENEFIT: $24,000 |

*Based on 3.5 operators @ $1,400/month

Validated Client ROI:

Finnish paper mill:

• Investment: 265,000•Annualreturn:265,000 • Annual return: 265,000•Annualreturn:288,000

• Payback period: 13.1 months