Discover how Auto Baler’s hydraulic waste press eliminates labor costs & boosts bale density.

Get CE-certified, IoT-enabled machines with 24h support. Download Specs!

Why choose a fully automatic horizontal hydraulic baler?

Experience seamless, hands-free baling with our fully automatic horizontal baler. Perfect for high-volume operations.

How about a traditional manual baler?

Requires a lot of labor

Uneven packing density

Low production efficiency

What can the fully automatic baling machine solve?

PLC fully automatic operation, reducing labor

High pressure compression, uniform density

Continuous feeding, uninterrupted packaging

How to choose the right horizontal baler for you?

“Safe design | Suitable for cartons, plastics, | Easy to operate”

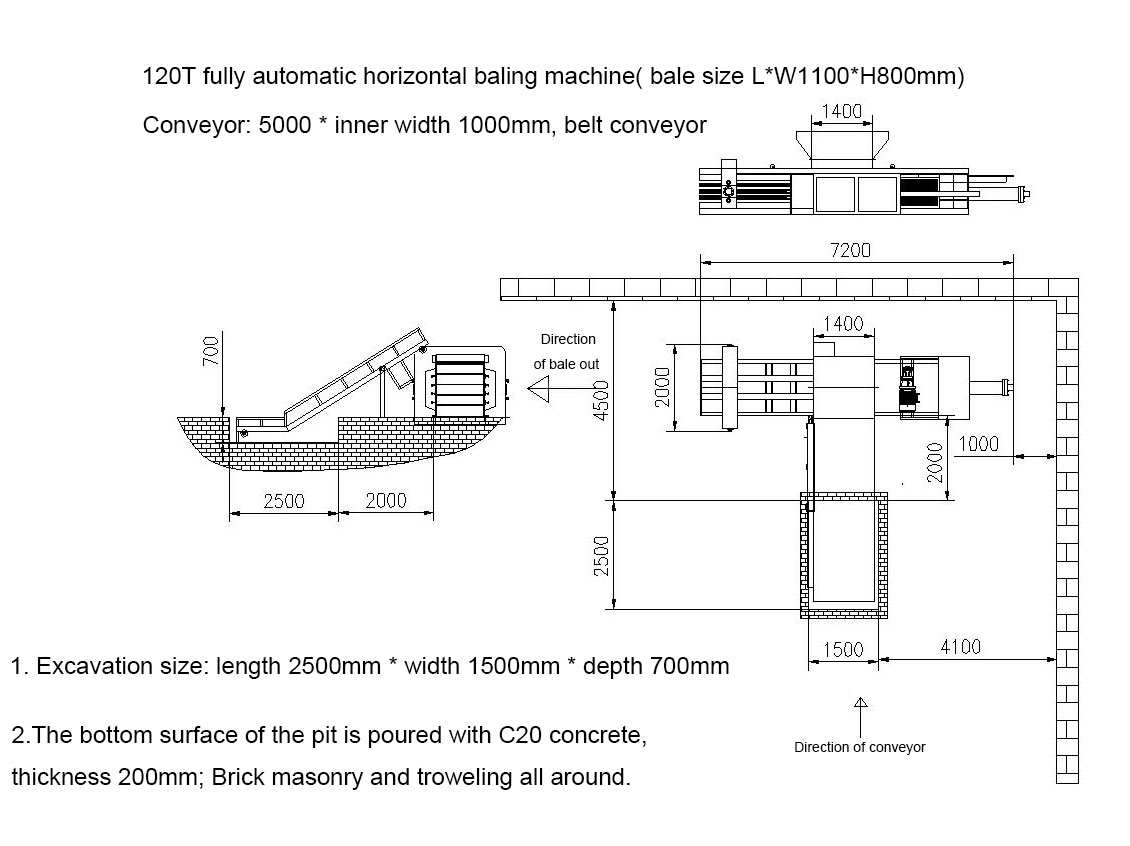

Pressure: Customer Cases 120T (Customization available, up to 300T+)

Degree of automation: Automatic packing , Manual rope threading , Manual rope binding

Baler size: L1700*W1100*H850 mm

Bale weight: 300-400 kg for PET bottles , 500-600kg for cardboard

Inlet: 1400*1100 mm

Main cylinder: 230 mm*2800 mm

Outlet method: Cylinder push bag

Working efficiency: 4-6 pieces/h

Operating system (Mitsubishi/Xinjie): Control box

Motor: 22 KW

Voltage: 380V/50 HZ/ 3phase/ 900 RPM

Install a lift door baler, increasing efficiency by 30% !

Saves 50% labor cost than traditional baler !

Q1: What waste materials can your auto baler compress?

A: Cuts 9+ material types with auto-pressure adjustment:

✅ Metal: Steel chips, copper wire, aluminum cans

✅ Plastic: PET bottles, film, PP bags (anti-stick coating)

✅ Paper/Cardboard: OCC, newspaper up to 25kg/m³ density

✅ Textile: Fabric scraps, used clothing

“Switch materials in 1 click via touchscreen – no manual reconfiguration.”

Q2: How much labor does an auto baler save?

A: Reduce 3 workers per shift with full automation:

Sensor-fed loading conveyor

Self-tying wire/strapping (500 bales/day)

Auto-eject palletizing

Philippines recycling plant case: Saved $5,200/month labor costs.

Q3: What makes Auto Baler’s compression more efficient?

A: 220-ton dual-piston system vs. standard 150-ton:

█▉▉▉ Auto Baler HD-300 (820 kg/m³)

█▉▉ㅤ Competitor A (650 kg/m³)

→ 26% higher density = Fewer truckloads & lower freight costs

Q4: How do you prevent breakdowns in high-volume operations?

A: Military-grade durability:

Hardox 450 wear plates (10x lifespan vs. mild steel)

IoT predictive maintenance (vibration/temp sensors)

72-hour global spare air shipping

0.3% downtime rate – industry average: 4.7%

Q5: Are auto balers safe for factory workers?

A: CE + UL-certified safeguards:

⚠️ Laser curtain halts operation if humans detected

⚠️ Emergency stop buttons (6 access points)

⚠️ 10-year accident-free record