Waste facilities overflow daily, creating costly chaos. Disorganized materials slow operations and slash profits. Automatic balers1 solve this by transforming workflows instantly.

Automatic balers compress recyclables without manual intervention, boosting throughput by 70% while requiring minimal supervision. This enables continuous processing of cardboard, plastic, and textiles – directly increasing recyclable value and reducing labor costs.

Manual handling simply can’t match modern demands. Automated systems revolutionize waste management. Discover key components that make this possible through real-world applications.

What is the function of the baler?

Chaotic waste consumes valuable space. Disorganized recycling streams drive up handling time. Industrial balers create order from this mess daily.

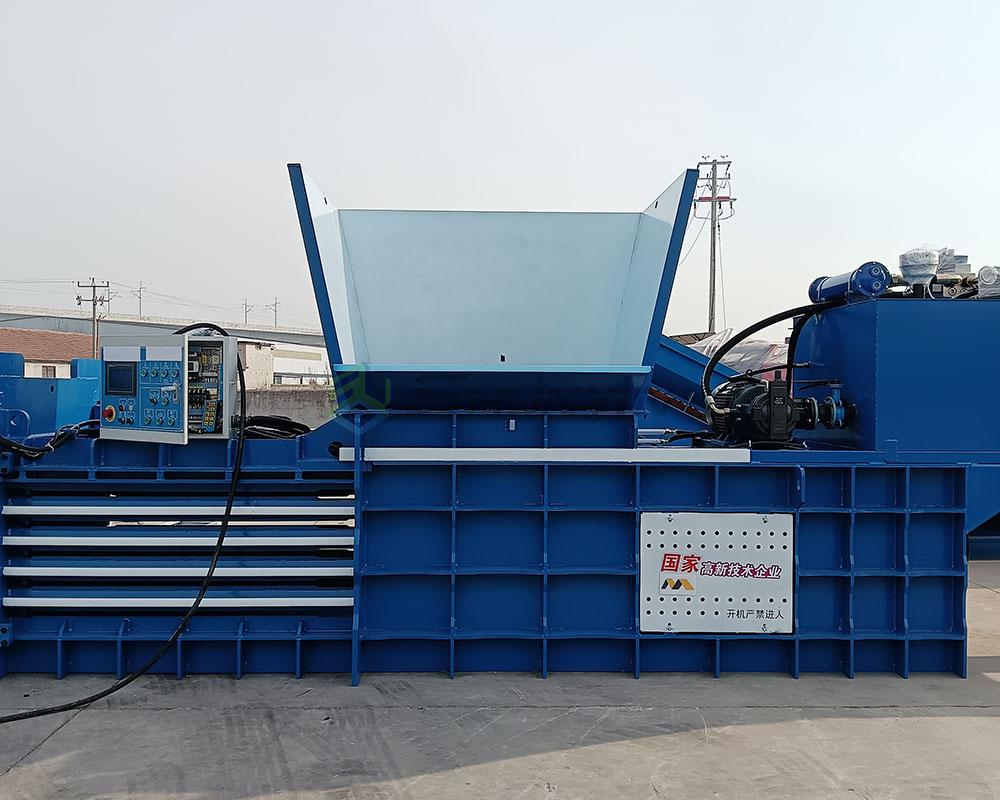

Balers compress loose materials into compact bales using hydraulic pressure. This reduces volume by 10:1, stabilizes materials for transport, and increases their resale value at recycling facilities.

How hydraulic compression transforms waste

The power comes from three core stages:

- Material intake

Conveyors feed loose items into the compression chamber - Cyclic compression

Hydraulic rams exert up to 150 tons of force - Bale ejection

Finished bales move to storage automatically

Real cost-saving impact

Last quarter, a Canadian distributor reported impressive results after installing our SY-1200 model:

| Before Baling | After Baling | |

|---|---|---|

| Monthly warehouse space | 200m² | 35m² |

| Shipping frequency | 3x/week | 1x/week |

| Material value increase | $22/ton | $48/ton |

Daily labor hours dropped from 8 to 1.5, freeing staff for value-added tasks. This efficiency isn’t isolated – similar outcomes occur across industries. For textiles or plastic? Film requires different compression than rigid plastics. Our engineers customize ram pressure and dwell time. Schedule free configuration advice at https://lemonchiffon-shark-638535.hostingersite.com/contact/.

What is an automatic waste sorting machine?

Contaminated loads degrade recyclable quality. Sorting errors create revenue loss and disposal fees. Automating this process ensures consistent material purity.

Automatic sorting machines use optical sensors, magnets, and air jets to separate materials by composition. They handle over 5 tons/hour with 98% accuracy while reducing human error.

Inside the sorting process

Three-layer precision drives results:

- Identification

Near-infrared scanners detect material composition - Separation

Targeted air jets divert items onto specialty lines - Quality control

Recheck sensors verify stream purity

Comparative efficiency analysis

A Singaporean client tested manual vs. automated sorting:

| Metric | Manual Crew | Our Auto-Sorter |

|---|---|---|

| Throughput | 0.8 tons/hour | 5.2 tons/hour |

| Contamination Rate | 13% | 1.7% |

| Operating Cost/Ton | $18 | $6 |

Higher-quality materials command premium prices. Aluminum bales with <1% contamination fetch 30% more. Most ROI periods are under 14 months. For multi-material facilities? Combine our balers with sorting lines for seamless processing chains. Get a layout plan today.

What does a recycling baler do?

Loose recyclables occupy excessive space and degrade during handling. Transport inefficiencies devour profits. Recycling balers convert problems into assets.

Recycling balers compact clean waste into standardized bales. This optimizes logistics by increasing load density 5x while protecting material integrity for higher resale value.

Value preservation process

Key stages maximize return:

- Containment prevention

Sealed chambers stop wind-scattering during compression - Density control

Adjustable pressure creates bale weights from 200-1200kg - Surface protection

Tensioned wire/strapping prevents disintegration

Material-specific applications

| Cardboard | Plastic Film | Textiles | |

|---|---|---|---|

| Optimal Pressure | Medium | Low | High |

| Bale Weight | 800kg | 500kg | 700kg |

| Value Boost | +$30/ton | +$65/ton | +$40/ton |

Japanese car manufacturers recover foam scraps worth $400/ton as acoustic insulation. Proper baling increases profit margins by 22% on average. Dealing with seasonal volume spikes? Horizontal balers like ours process surge capacity without additional labor. See throughput videos on this page: https://lemonchiffon-shark-638535.hostingersite.com/contact/.

What is waste baling?

Unbaled materials incur hidden costs. Low-density loads mean more truck trips – increasing fuel and handling expenses. The solution lies in strategic compaction.

Waste baling consolidates recyclables into high-density blocks. This reduces transport volume by 90%, lowers handling frequency, and stabilizes materials for efficient storage and resale.

Industrial-scale baling workflow

-

Pre-baling preparation

Sort and clean materials to avoid contamination -

Compression loading

Feed materials through conveyor systems -

Compression cycle initiation

Sensors activate hydraulic rams at full capacity -

Tying and ejection

Automatic systems bundle finished bales for removal

Economic impacts quantified

A North American recycler documented these savings:

- Transport costs

Down from $17,000 to $3,500 monthly - Storage space

Reduced from 3 warehouse zones to half zone - Material degradation

Water damage loss decreased by 92%

These systems pay for themselves in 8-18 months. Need customized dimensions? Our balers produce export-spec bales ranging from 700x800mm to 1100x1300mm. Request dimension sheet download here.

Conclusion

Automatic balers1 revolutionize waste management – compressing materials efficiently while slashing costs and boosting recycling profitability dramatically.