Shunyin’s vertical baling machines are compact, high-quality solutions for efficient waste compression. Perfect for tight spaces, they offer customizable features to suit various materials and volumes. These machines are built for durability and reliability, providing consistent performance at competitive prices. With our focus on quality control, certifications, and timely delivery, Shunyin ensures you get the best value. Trust us for your vertical baler needs and streamline your operations with a machine designed to last.

Yes, our vertical hydraulic balers can be customized in both size and function to meet your specific needs. We offer flexibility in design to ensure the machine fits your operational requirements. Please feel free to share the details, and we can provide a tailored solution at a competitive price.

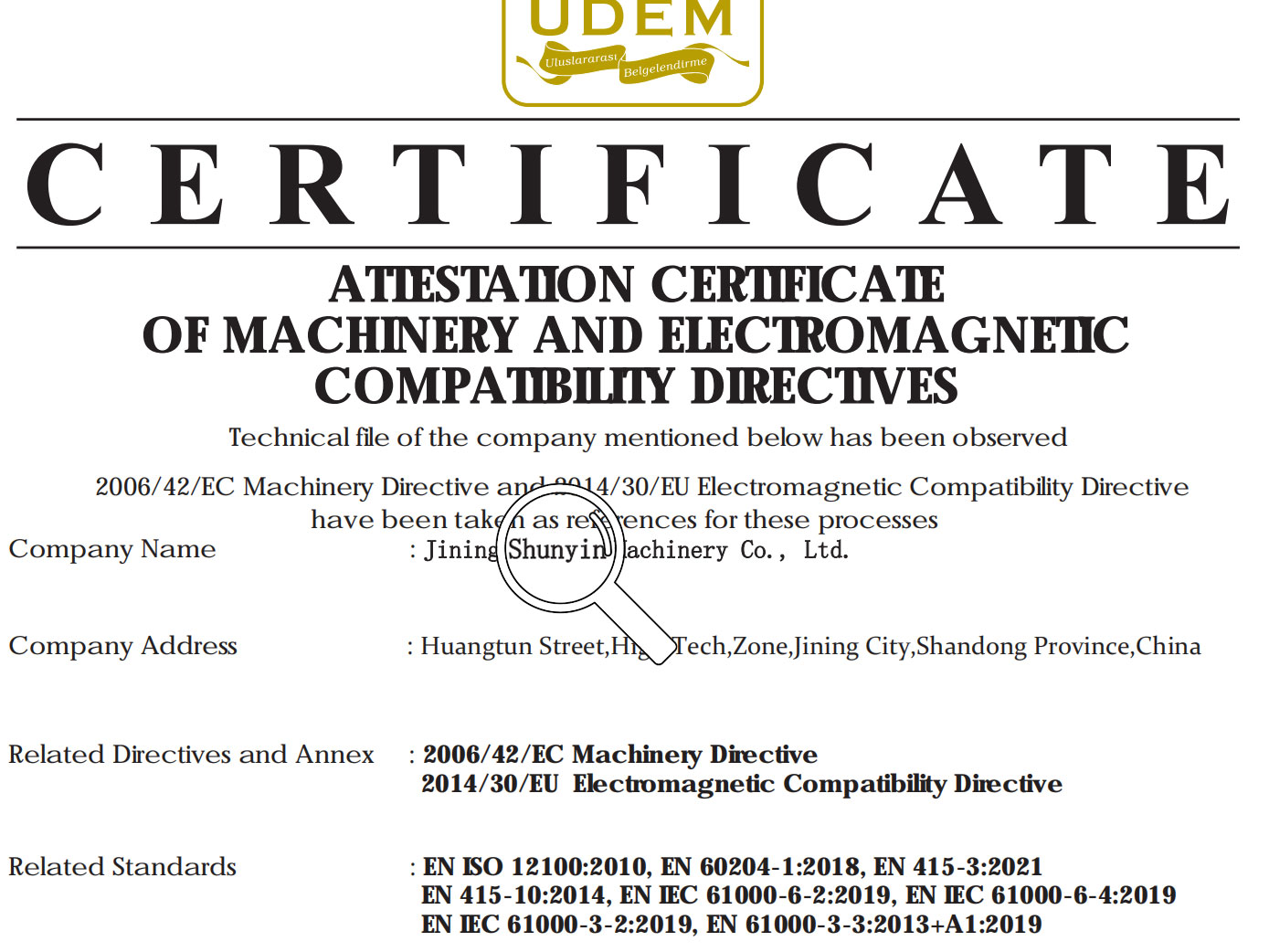

Yes, our products are certified with ISO and CE standards. These certifications ensure that our horizontal and vertical hydraulic balers meet international quality, safety, and environmental requirements.

We also provide additional certificates upon request, depending on the specific needs of our customers. This helps guarantee that the machines are reliable, safe, and comply with global industry standards.

If you would like to receive copies of these certifications or have any specific certification inquiries, feel free to contact me, and I will be happy to provide them.

Yes, we offer both warranty and after-sales service for our hydraulic balers:

Warranty:

– Our standard warranty period is one year from the date of delivery.

– During this period, we cover any defects in materials or workmanship at no additional cost.

After-Sales Service:

– Technical Support: We provide assistance with installation, troubleshooting, and ongoing machine maintenance.

– Spare Parts: Access to replacement parts is available, and we ensure that you receive high-quality, cost-effective components.

– On-site Support: If necessary, we can send technicians to assist with machine setup or repairs at your location.

– Regular Maintenance: We offer guidance on proper machine maintenance to maximize the lifespan and efficiency of the balers.

Our goal is to ensure that the machines run smoothly throughout their lifespan, and we are committed to offering timely and reliable support.

Yes, like any hydraulic equipment, our vertical hydraulic balers have parts that may require regular maintenance. Common vulnerable parts include seals, hydraulic oil filters, and valves. These components may need periodic checks or replacements to maintain optimal performance.

We recommend regular maintenance to ensure long-lasting functionality. Regularly checking the seals, replacing hydraulic oil filters, and monitoring hydraulic fluid levels are essential to avoid wear and tear.

We can also provide guidance on maintenance schedules and offer replacement parts as needed. If you require further assistance, please let us know!

Our vertical hydraulic balers come with a standard warranty period of 36 months from the date of delivery. During this time, we provide support for any manufacturing defects or malfunctions.

For on-site repair service, we do not directly offer this, but we can assist in coordinating with local technicians or provide remote troubleshooting support to help resolve issues.

Additionally, we offer spare parts supply support. We keep essential parts in stock and can ship them quickly to minimize downtime for your machine.

Please feel free to reach out if you have more specific needs regarding warranty or services!

Our vertical hydraulic balers use high-quality hydraulic pumps and valves sourced from well-known brands. We use brands such as Parker, Bosch Rexroth, and Eaton, which are recognized for their reliability and performance in industrial applications.

The specific models and pressure levels may vary based on the machine’s configuration and your customization requirements, but typically, we use hydraulic pumps with pressure levels ranging from 160 bar to 250 bar for optimal performance and efficiency. These pumps and valves are selected to ensure smooth operation and durability.

If you need more detailed specifications for a specific model or customization, feel free to reach out!

The maximum working pressure of our vertical hydraulic balers’ hydraulic system typically ranges from 160 bar to 250 bar, depending on the specific model and customization. This pressure is more than sufficient to handle most packaging needs, especially for compacting materials like cardboard, plastics, and paper.

If you have specific requirements for your packaging materials or need a system that can handle higher pressures, we can discuss further customization options to meet those demands. Please let us know your packaging requirements, and we will ensure the baler fits your needs!

Yes, our hydraulic systems use high-quality hydraulic oil that is designed for optimal performance and longevity. We recommend using hydraulic oil that meets industry standards and provides excellent lubrication and heat dissipation properties.

Regarding the oil pipes, we ensure that they are made from materials with high pressure resistance and corrosion resistance. This helps maintain system integrity and extends the lifespan of the machine.

Oil Replacement Cycle and Maintenance:

- Oil Replacement Cycle: Generally, we recommend replacing the hydraulic oil every 2,000 to 3,000 working hours, depending on the operating conditions and oil quality.

- Maintenance Requirements:

- Check oil levels regularly and top up if necessary.

- Inspect oil quality for any contamination or degradation. If the oil becomes dirty or thick, it should be replaced.

- Clean oil filters regularly to prevent blockages and maintain system efficiency.

By following these guidelines, you can ensure the hydraulic system operates smoothly and efficiently for longer periods.

Feel free to ask if you need more specific details!

Yes, the material of the compression chamber in our vertical hydraulic balers is designed to be wear-resistant and durable. We use high-quality steel that can withstand the pressure and wear associated with continuous use, ensuring the longevity of the baler. The chamber is built to handle high-strength packaging requirements, making it suitable for compressing a wide range of materials like waste paper, plastics, and other recyclables.

Compression Chamber Size Adaptability:

The size of the compression chamber can be customized to suit your specific packaging materials. Whether you’re dealing with waste paper, plastic, or other materials, we can adjust the chamber dimensions to optimize the baler for your needs. This flexibility allows for efficient compression, helping to save space and improve handling.

If you have specific packaging material sizes or requirements, feel free to provide the details, and we’ll ensure the machine meets your needs perfectly!

Yes, the packaging force (tonnage) of our vertical hydraulic balers is designed to meet a wide range of production requirements. The balers are available with varying tonnage options, typically ranging from 20 tons to 80 tons, depending on the model and customization.

This packaging force is sufficient for compressing materials such as waste paper, plastics, and textiles, among others. If you have specific production needs or higher tonnage requirements, we can discuss further customization options to ensure the baler meets your exact production demands.

Please share more details about your production requirements, and we’ll tailor the solution for you!

Yes, our vertical hydraulic balers are designed to effectively compress materials to the appropriate density for packaging. The machine’s adjustable pressure settings allow you to control the density of the bales based on the type of material being processed, whether it’s waste paper, plastics, or textiles.

By adjusting the compression force and cycle time, the baler can produce bales that meet your specific density requirements, making the packaging more compact and easier to handle for storage or transport.

If you have specific density targets for your materials, we can discuss the best settings and configuration to achieve optimal results. Let us know your exact needs!

Yes, our vertical hydraulic balers support a variety of strapping straps, including both steel straps and plastic straps. The strapping system is versatile and can be adapted to different materials, giving you flexibility depending on your packaging needs.

Adjusting Strap Tension:

The tension of the strapping straps can be easily adjusted using the machine’s control panel. The tension can be set to suit the type of material being compressed, ensuring a secure and tight bundle. For steel straps, the tension is usually higher to ensure a firm hold, while for plastic straps, it can be adjusted for a slightly lower tension.

The machine comes with a built-in tension adjustment mechanism, so you can fine-tune it based on the material and required bundling strength.

If you need guidance on how to adjust the tension or have specific strap preferences, feel free to let us know!

The strength and uniformity of the strapping in our vertical hydraulic balers can be controlled through a few key features:

Controlling Strength and Uniformity:

- Tension Adjustment: As mentioned earlier, the tension of the strapping is adjustable through the control panel. This allows you to control the strength of the strapping based on the material type and packaging requirements. Proper tension ensures uniform bundling and prevents loose or uneven straps.

- Consistent Feed: The strapping system is designed to provide a consistent feed of straps to ensure uniform wrapping around the bales. This helps achieve even strapping across the entire bundle for better strength and uniformity.

Strapping Strap Replacement:

The strapping straps are easy to replace. The system is designed for quick and simple loading of new straps, minimizing downtime. Both steel and plastic straps can be replaced with ease, and the process typically involves loading the new strap into the machine’s feeder and adjusting the settings accordingly.

If you need more detailed instructions on replacing the straps or have specific questions, feel free to reach out!

Yes, the speed and accuracy of the strapping system in our vertical hydraulic balers are designed to meet the demands of a high-paced production environment.

Speed:

The strapping system operates at a consistent speed, ensuring that strapping is completed quickly after each compression cycle. This allows for continuous operation without delays, keeping up with your production rhythm. The machine’s automated strapping cycle reduces manual intervention, improving overall efficiency.

Accuracy:

The system is designed to deliver accurate and reliable strapping, ensuring that each bale is securely strapped with uniform tension. The automated process ensures the straps are applied precisely, preventing slippage or uneven bundling.

If your production rhythm requires specific adjustments in speed or further customization, we can work together to ensure the strapping system aligns perfectly with your needs. Let us know how we can help!

Yes, the frame and body structure of our vertical hydraulic balers are built to withstand high-load operations. We use high-strength steel for the frame, ensuring the equipment can handle the pressure and force generated during continuous, heavy-duty use. This robust construction ensures durability even under demanding conditions.

Corrosion and Wear Resistance:

The materials used are resistant to corrosion and wear. The frame is often coated with anti-corrosion paint or treated with special coatings to protect it from rust and wear over time. Additionally, key components are designed to resist abrasion, maintaining the machine’s performance in environments with heavy usage.

This combination of strength, durability, and corrosion resistance ensures the equipment performs reliably for long periods.

If you need more details or specific material specifications, feel free to ask!

Yes, the key components of our vertical hydraulic balers are made of durable materials specifically designed to prevent wear and ensure long-lasting performance.

Key Durable Components:

- Compression Chamber: Made of high-strength steel to resist deformation and wear during continuous operation.

- Hydraulic System: All hydraulic parts, including pumps, valves, and cylinders, are made from high-quality, durable materials to withstand high pressure and reduce the risk of wear over time.

- Seals and Gaskets: These are made from wear-resistant, high-quality rubber or synthetic materials to prevent leaks and ensure proper function throughout the machine’s lifespan.

- Strapping Mechanism: The components involved in the strapping process are designed to be durable, with materials resistant to friction and wear, ensuring smooth and efficient operation.

Design for Wear Prevention:

We focus on designing the components with wear prevention in mind. Key parts that are prone to wear (such as the compression plates, seals, and hydraulic components) are reinforced and regularly tested for durability.

If you need more specific details about the materials used or have concerns about wear and tear, feel free to reach out!

Yes, our vertical hydraulic balers are equipped with several safety protection features to ensure safe operation:

Key Safety Features:

Emergency Stop Button: The baler is equipped with an easily accessible emergency stop button that immediately halts the machine in case of any emergencies or malfunctions, preventing further damage or injury.

Overload Protection: The baler is designed with an overload protection device that prevents the system from operating beyond its maximum capacity. This feature helps to avoid damage to the machine and ensures the safety of operators.

Other Safety Measures:

- Safety Guards: Protective barriers are in place around moving parts to prevent accidental contact.

- Safety Lockout Mechanism: The baler includes a safety lockout feature to prevent operation during maintenance or when the machine is being serviced.

- Pressure Relief Valve: Ensures the hydraulic system does not exceed safe pressure limits, reducing the risk of system failure.

Compliance with International Safety Standards:

Our machines are designed to comply with international safety standards, including CE certification (for European markets) and other applicable safety regulations. The safety features are thoroughly tested to meet these standards, ensuring reliable and secure operation in any work environment.

If you have specific safety compliance requirements or concerns, we can provide further details or certificates as needed.

Yes, our vertical hydraulic balers are equipped with protective covers for the mechanical transmission parts. These covers are designed to prevent accidental injury during operation by shielding moving parts such as gears, pulleys, and belts.

Protective Features:

- Safety Guards: The mechanical transmission components are fully enclosed or covered with sturdy, protective guards to prevent contact with operators or bystanders.

- Easy Access for Maintenance: The covers can be easily removed for maintenance or inspection, while still ensuring safety during regular operations.

These safety features are in place to minimize the risk of injury and ensure a safe working environment.

If you have specific concerns about safety or need further details, feel free to ask!